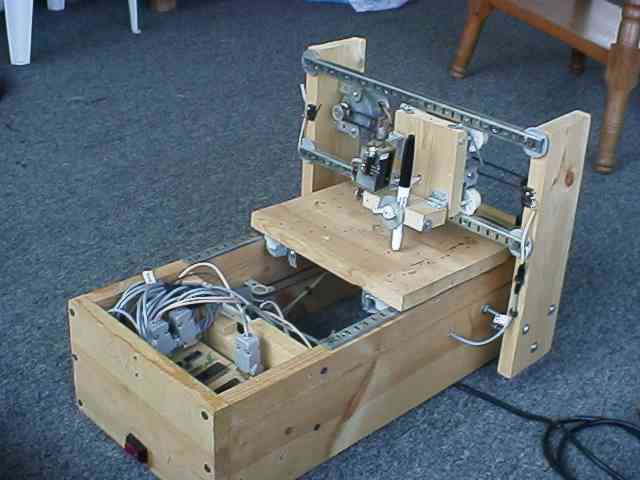

PCB Plotter (prototype)

PCB Plotter (prototype) | Description | 3-axis PCB plotter |

| Processor | Intel 8749 Micro |

| 2 Motors | 4-Phase Steppers |

| Power | 12V/5V Dual-Voltage Power Supply |

| 4 Limit sensors | 2 X-axis, 2 Y-axis |

| Digital Signals | 1 Output, 1 Input |

| Date Created | August 1993 |

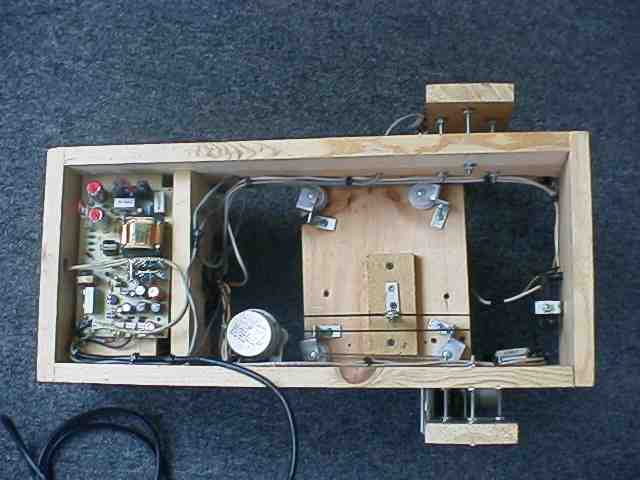

The plotter has 2 moving platforms

platforms,

each of which has a set of 4 large nylon rollers which ride on metal

tracks.

The large, horizontal platform functions as a table on which a circuit

board is placed. The smaller, vertically mounted platform

provides

support and mounting for the pen actuator.

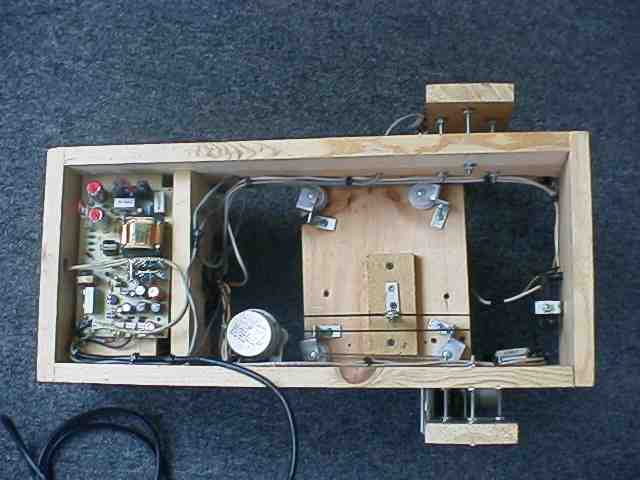

Underside view |

Underside view, power supply |

The plotter is controlled by a

custom-designed

intelligent STPC-10 stepper controller. This controller provides

simulatneous control of 2 stepper motors. It also provides +/-

inputs

for limit sensor switches which automatically shut off a motor when the

limit is actuated. Also provided is 1 digital input and 1 digital

output. The application of these signals is

user-specifiable.

For the purpose of the plotter, the digital output is used to control

the

solenoid pen actuator. The digital input confirms the position of

the pen, up or down.

The host software was also

custom-developed,

written in C. This software contains a simple GUI for designing a

circuit using pads and traces. Once the circuit has been

designed,

the user prepares a bare copper-clad board, loads a marker pen, and

starts

the plotter. Once the plot has completed, the board is

ready

to be etched and drilled.